TSL Engineering S.r.l. was the first company to deal with the problem of the behavior of safety barriers installed on soils of poor consistency, and to experiment with different solutions. The project, called “Sistema S.C.Re.W.S.®”, Save Crash Reinforcing Weak Soil, allows the adoption of innovative solutions for the reinforcement of the support soil that allow to increase the performance of the barriers and to use the crash test data already performed, without having to foresee others.

TSL Engineering S.r.l. is also able to continuously monitor, through the “Re.T.I.M.” – Real Time Inclination Measurement – the deformation state of installations on works of art or anchored by plates and bolts, along road and railway networks, which, subjected to the constant action of cyclic loads, could represent a danger for users due to of the possible loss of grip to the foot and decrease in the performance of structural performance.

TE.SI.

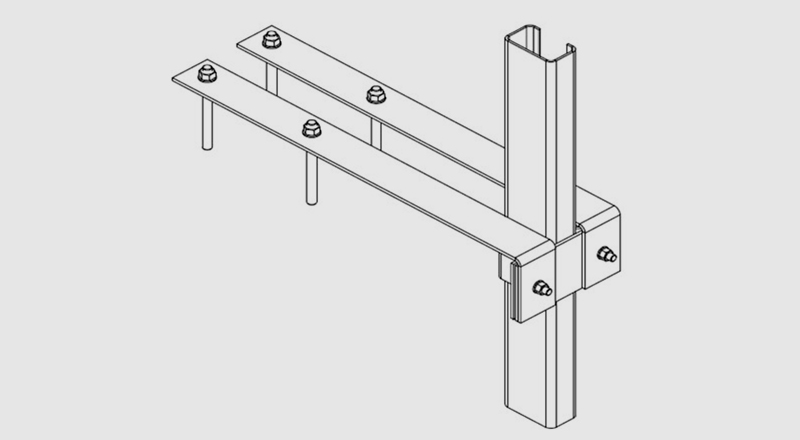

The first study dates back to 2014 when TSL Engineering began studying the TE.SI. (Safe Grounds). The product, patented in 2015, consisted of a tie that wraps around the barrier post at ground level and, through a horizontal connection element directed toward the roadway, transfers stresses to an embedded part of the pavement.

SCREW

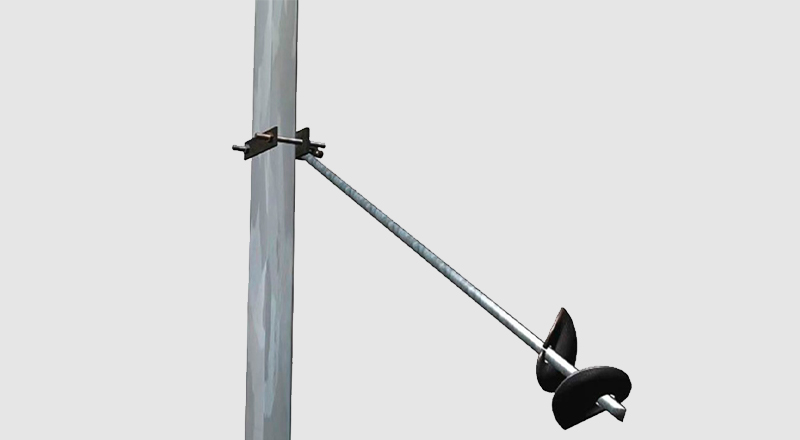

In 2016, work began on another product, called SCREW (screw) patented in 2017; the operating principle is that of a bar connected to the base of a post and infixed, by rotation or percussion, at a defined angle behind the barrier toward the roadbed. Therefore, the operating principle, is that of a screw clinging to the ground thanks to protrusions in the embedded part.

SCREW, compared with Te.Si., has no interference with the roadbed, higher performance, and easier installation.

A.TO.S.

In 2019, TSL Engineering began studying a third product called A.To.S.® - Anchorage Tool for Soil, patented in 2020.

The product has a different working principle from the previous ones, guaranteed by a rigid tie-rod, slanted infixed into the ground on the back of the barrier toward the pavement, consisting of a profile with no surface protrusions, and a rigid attachment with the stake.

A.To.S., compared with SCREW, avoids bending phenomena and overcomes installation issues that have arisen in the presence of particularly compact subgrades.

Re.T.I.M.

The self-powered system Re.T.I.M., allows to measure in real time the deformations of the structural elements, sending alarm signals, via the IoT network. Suitable for very high barriers, such as noise barriers, integrated noise / safety barriers, wind barriers, lighting poles and portals. The data is stored and available on a dedicated web platform.