A.To.S. is a system designed and patented by TSL, which is applied directly to the uprights of road barriers installed on low consistency soil, to ensure proper operation of the barrier in case of impact and to avoid consolidation works.

To ensure the performance of the barrier installed at the site of installation is as expected, the soil on which the barrier is tested must have the same characteristics as the soil on which it is installed since the smooth operation of a barrier is ensured by the proper interaction of the installation pile/soil.

Very often, devices installed at the edges of road infrastructure are embedded in substrates of poor consistency resulting in a loss of device performance.

How it works

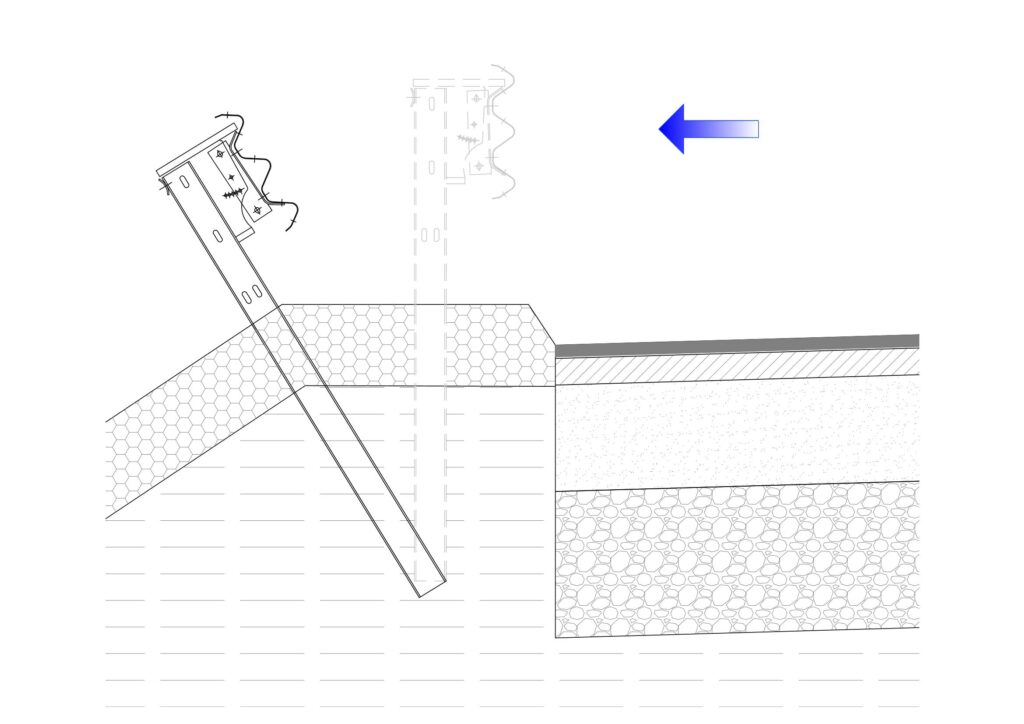

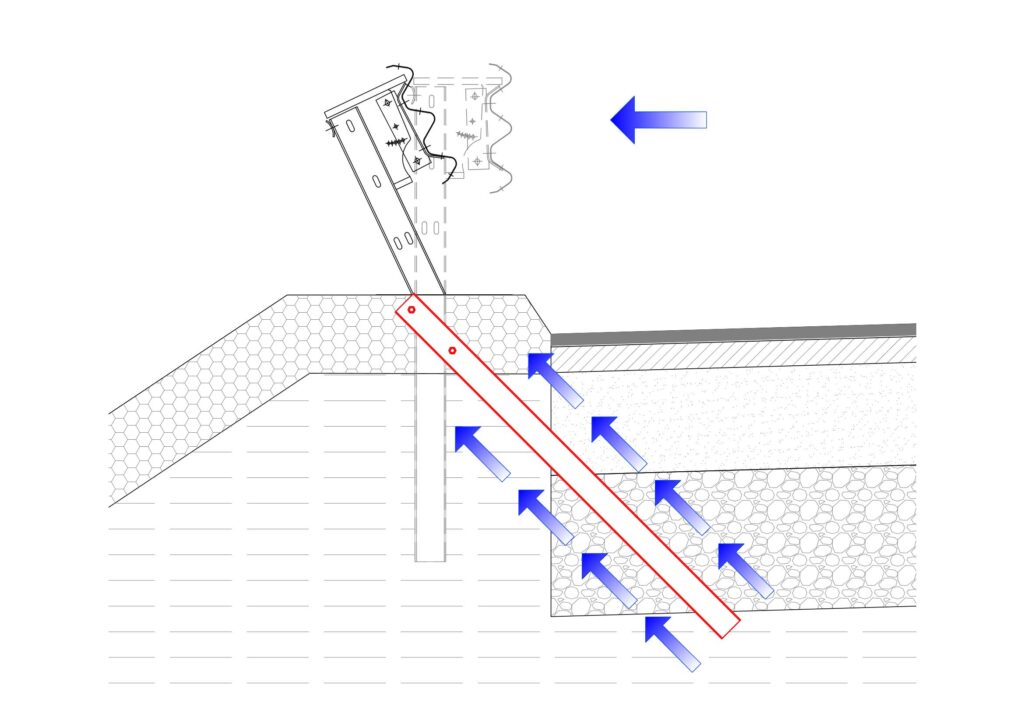

In those situations where the posts of safety barriers fail to perform as they should, A.To.S. provides them with the necessary resistance by transferring the stresses produced by impact loads to the roadbed whose mechanical characteristics are better than those of the embankment. The anchoring system will allow the pile to flex in a predefined area and, through its plastic deformation, properly dissipate impact energy, in a manner comparable to that of a crash test.

Design and installation

The A.To.S. system is always properly sized before installation to verify proper operation at the installation site.

Prior evaluation of the installation site by performing dynamic tests.

Evaluation of the need for the A.To.S. system, through a comparative analysis with similar dynamic tests performed in the test field.

Sizing the A.To.S system through preliminary comparison tests or finite element numerical analysis.

Validate proper sizing through dynamic in-situ testing. At this point, the system can be installed in situ.

The A.To.S. system can be installed quickly from the roadside without the need to disassemble the device to which it is applied, it does not require any demolition and restoration, and it does not require fixed construction sites while interfering minimally with vehicular traffic.

Strengths

- Ensures the proper operation of safety barriers and integrated barriers installed on poor soil texture

- Custom designed and applies to new and existing barriers

- Has been validated by a robust testing program

- Does not require disassembly of any components of already installed devices

- Does not interfere with the road surface or sub-services

- Has reduced cost and time for production, installation, and site construction

- Responds symmetrically along the three axes in case of non-frontal impact

- Has no problems with bar flexibility

- Tightly connected to the pole

- Does not require maintenance or replacement in case of impacts

Validation

TSL performed a series of crash tests, from life to static and dynamic tests on different devices installed on supports with different characteristics, and numerical finite element simulations aimed at validating and defining the main characteristics of the system.

Thanks to the extensive testing program, it is possible to use, for operational simplicity, the dynamic test to verify the functioning of the posts even with reinforcing elements.

Static or dynamic horizontal thrust tests alone applied orthogonally to the axis of the barrier, are not sufficient because in reality, during impacts, the posts tend to deform in the direction where they find less resistance or even slip off.